Currently Empty: ₦0

About Course

Course Overview

At the end of the course, you will be able to:

– Design and execute automation projects.

– Program, troubleshoot, and maintain continuous signal field devices such as level meters, VFDs, temperature sensors, pressure sensors, modulating valves, etc.

– Establish communication between two or more PLCs.

– Design process control systems with PID controls.

Course Content

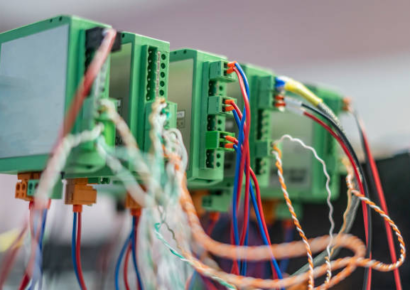

– Set up, wiring, and operation of continuous signal devices such as VFDs, flow meters, temperature sensors to PLCs.

– Continuous signal (analog) programming.

– Introduction to S7 function blocks (FBs), Function Calls (FCs), Special Function Blocks (SFBs), and Special Function Calls (SFCs) and their applications.

– Connecting and communicating between two or more PLCs.

– Profibus connections and programming.

– Process control using PID loop programming (with practical sessions).

– Introduction to process controls.

– Open and closed loop controls.

– Introduction to PID concept and applications.

– PID programming.

– PID tuning.

– Introduction to HMIs (WinCC).

Duration: 1 month